Municipal Waste

Evidence shows that Sewage Treatment Works (STWs) have almost continuous issues with foam, including foaming problems in digesters, activated sludge plants and centrifuges. Controlling this has traditionally required many tons of antifoam chemical every year, which can become very expensive. Also, foam can cause very expensive damage due to blocking filters and causing over-pressurisation, as well as damaging gas compressor blades. It is not unheard of for the roof of a digester to be pushed off by excess foam, resulting in repair costs that run into millions of pounds.

Bulking sludge and foam are two undesirable, complicated and unpredictable challenges for many treatment plants. In many cases, the filaments and filamentous bacteria, such as Nocardia and Gordonia, which cause bulking in sludge tend to float and thereby produce huge amounts of foam. The foam may vary in depth considerably and extend throughout the biological circuit, as well as to anaerobic digesters and dewatering units.

The traditional approach is to dose antifoam into the process continually. This dose rate is typically set to cope with foam during the plant’s peak demand. However, on average, this is far too high, and in some systems, there is little or no foam generation for most of the time. Alternatively, the addition of chemicals is often done randomly, in far too large quantities and too late. This reactive approach results in very limited control and understanding of the entire process.

In some cases, the WWTP can suffer for years without finding a sustainable solution to the problem. These chemicals themselves may also add to the foaming problem. In both cases, the high cost of chemicals and energy through unnecessary pumping can be substantial. Additional charges are also incurred through excessive equipment wear and damage. The use of foam monitoring and control technology is poised to have a big impact on the industry.

Industrial Wastewater

Many industrial processes involve cleaning water before it can be discharged to the local sewer. This cleansing may involve removing solids and heavy metals and adjusting pH balances. The clean-up processes often involve air injection, for example, DAF, activated sludge and flocculation, which can cause foam to develop in dirty water. The nature of the materials in such effluent varies from time to time. So, the tendency to foam will change. The process can be controlled at a minimum cost by detecting when foam has reached a critical level and dosing antifoam. Doing this is far more efficient than previous automatic dosing methods.

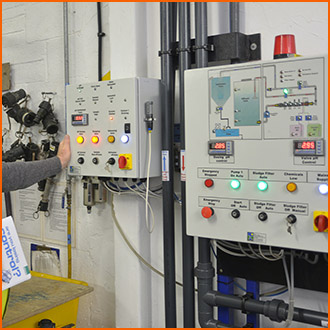

Hycontrol’s highly versatile SureSense⁺ Foam Control systems have been specifically developed for measuring the thickness of the foam in a process and for detecting foam-liquid interfaces. The patented technology behind these systems originated from detailed research into foam control during pharmaceutical fermentation. Hycontrol points out that the special measuring sensors and control equipment have been designed specifically for foam control and are not modified level sensors.

|