| HOME | APPLICATION GALLERY | WHY MEASURE FOAM? | HOW DOES IT WORK? | REDUCE COSTS | REQUEST A QUOTE |

WHY MEASURE FOAM? |

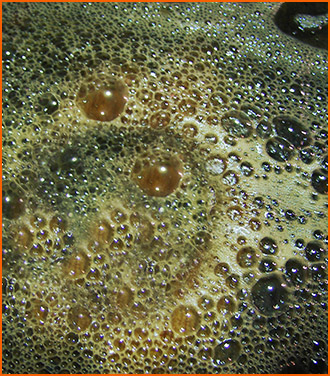

Foam is a very common element of industrial processes where liquids are stirred, or liquids and gases are mixed.Foaming affects almost every industrial sector: from pharmaceuticals to brewing, from paint manufacture to wastewater treatment, from oil & gas to food processing, from textiles to pulp and paper. The foam may be an integral and important part of a process, or it may be an unwanted side effect. It has the appearance of a simple material. In practice, foam is a very complex, dynamic material with its production involving physical, chemical and biological processes. This complexity can have a significant impact on industrial processes. Foam-over events can damage equipment, ruin product batches and lead to environmental pollution. By measuring and controlling foam, we can improve safety and efficiency in our applications. However, to do that, we must first understand what foam is and why measuring it can be a problem. Properties of FoamMost common foams are made up of an unstable, two-phase medium of gas and liquid, with a structure consisting of gas pockets trapped in a network of thin liquid films and plateau borders. Several conditions are needed to produce foam: you require both a liquid and a gas, and there must be agitation, which may be generated by mechanical agitation, mixing, stirring or sparging. Also, there must be surfactants (surface active components) that reduce the surface tension of the liquid. When the foam is present, there is always a natural drainage along the thin films of liquid between the bubbles. Fluid gradually drains down from top to bottom, creating a density gradient through the column of foam. The foam at the top of the column collapses as the films become too thin to support the bubbles. An equilibrium develops between this material collapse at the top and new foam building up from the liquid surface below. This ongoing process limits the maximum height of the foam column. However, in some processes, foam stabilising agents such as proteins reduce the drainage, resulting in much more stable foam. In these circumstances, the foam production rate can far exceed the dispersal rate, and the foam can build up to a problematic level. Proteins are long-chain molecules; by lying along the thin films between the bubbles, they restrict or prevent the drainage of liquid, allowing the column to continue to grow. The stability of such foams has a large impact on their lifetime. Problems with Foam in Industrial ProcessesAdditional factors, such as poor system design and leaking pumps, can exacerbate foaming problems. In a digester, there are even more complications to consider, including changes in temperature, feedstock, and pH. But regardless of the specific application, in all instances minimising the impact of foam requires effective monitoring, measurement and control. For example, in Anaerobic Digestion foam can block up pressure valves and cause over-pressurisation, damaging the digester and causing leakage. Foam can also get into a gas exit line and damage valuable process equipment like compressors. Foam causes major issues in processes when it gets out of control, be it AD, waste treatment or food preparation. It needs to be carefully monitored to counter these problems. It should be a major priority for the industry to get right. As industries increase in size, for example, in the booming AD sector, there are sure to be a rise in the number of incidents. Why Regular Level Probes Fail in Foam ApplicationsFoam measurement is difficult because foam, by its very nature, is insubstantial and highly variable. It contains only a small quantity of water or other liquid and a large amount of air or other gas. What we see when looking at foam are liquid surfaces made up of thin films. It may appear to have physical substance, but inside it is almost entirely gas and so is hardly distinguishable from the surrounding atmosphere. In practice, the measurement of foam has to be able to detect very thin films of liquid which may be less than 1% by volume of the total foam. Additional factors, such as poor system design and leaking pumps, can exacerbate foaming problems. In all instances, to minimise the impact of foam, it needs to be effectively monitored, measured and controlled. As the foam is at most 1% liquid and varies in density and liquid content throughout, attempting to measure it with a liquid measurement device will inevitably give unreliable results. It is clear that to detect foam accurately, a device that has been developed for that purpose is needed. Hycontrol sells all of the major current level measurement technology types and would not recommend any of them to detect foam. How to Measure and Control FoamIt is essential to understand the characteristics of the foam to understand it. Then one must measure its thickness and, in some applications, where the foam-liquid interface resides. The traditional approach to foam control is to add a defoamer chemical to the process at a constant rate. This method is very hit and miss and is expensive, wasteful and not very reliable. By measuring the foam and detecting it has reached a significant level, it is possible to automatically use the optimum amount of antifoam only when it is required. This measurement significantly reduces the cost while also improving the process control and reducing the risk of high levels of foam. It is, therefore, clear how important it is to implement effective foam control. There have been attempts to monitor foam using current level probe technologies adapted for foam measurement. In most applications, these fall short of providing either an adequate or sustainable solution. Now, a highly versatile range of foam control systems have been specifically developed by Hycontrol to fulfil a variety of functions, including:

The technology behind these systems originated from detailed research into foam control during pharmaceutical fermentation. The special measuring sensors and control equipment have been designed specifically for foam control and are not modified level sensors. It is important to emphasise that Hycontrol’s foam detection sensors are tools that have been specifically created for this task alone. |

| SEE - WHAT IS IMA SENSING? |

|

|

|

| WHAT IS IMA SENSING? | TECHNICAL SUPPORT | INSTALLATION | SERVICING | SURESENSE | CASE STUDIES | DOWNLOADS | CUSTOMERS | ABOUT HYCONTROL |

| HYCONTROL LTD Larchwood House, Orchard St, Redditch B98 7DP UK. Tel: +44 (0)1527 406800 Email: sales@hycontrol.com |